10 Best Innovations in the Chemical Manufacturing Industry?

The chemical manufacturing industry is at a pivotal moment, driven by innovation and technology. Experts like Dr. Helen Schwartz emphasize, “Innovation is the lifeblood of the chemical sector.” This industry faces challenges such as sustainability and efficiency, pushing manufacturers to rethink their processes.

Recent advancements showcase remarkable solutions. For instance, the integration of AI in production lines enhances precision and minimizes waste. Companies are adopting green chemistry principles, reducing harmful emissions and promoting eco-friendly practices. However, not all innovations succeed; some technologies fail to meet expectations. It’s a reminder that progress requires careful analysis and reflection.

The future of the chemical manufacturing industry lies in embracing change while learning from past mistakes. Each innovation presents an opportunity for growth and improvement. As the industry evolves, the focus must remain on creating sustainable and efficient processes that benefit both the economy and the environment.

Overview of Chemical Manufacturing Innovations

Innovation in the chemical manufacturing industry is crucial for sustainability and efficiency. Recent reports indicate that advancements in processes and materials can reduce production costs by up to 30%. One significant area of improvement is in green chemistry. This approach minimizes waste and promotes the use of renewable resources. Companies are adopting alternative solvents and catalysts to lessen environmental impact.

Another noteworthy innovation is automation and digitalization. Industry 4.0 technologies enable real-time monitoring and control of chemical processes. Sensors collect data that help optimize operations. Predictive analytics can foresee equipment failures, reducing downtime by 20% or more. While these advancements promise efficiency, there is a learning curve for workforce adaptation.

Tip: Embrace continuous training for staff to maximize the potential of new technologies.

Emerging bio-based chemicals also show promise. Reports show a potential market growth of 12% annually. However, the transition to bio-based processes can be challenging, requiring investment in R&D. Companies must balance immediate needs with long-term sustainability goals.

Tip: Collaborate with research institutions to explore innovative bio-solutions.

Advancements in Sustainable Chemical Production Methods

The push for sustainability in the chemical manufacturing industry has led to remarkable innovations. One key advancement is the development of bio-based chemicals. These are derived from renewable biological materials, significantly reducing reliance on fossil resources. They help minimize carbon footprints, which is a crucial step towards a greener future.

Another promising area is the use of green solvents. Traditional solvents often pose environmental hazards and health risks. In contrast, green solvents are safer and more eco-friendly. They enable safer processes without compromising efficiency. However, their adoption is not widespread yet, and the challenges remain in scalability and cost-effectiveness.

Recycling and waste reduction techniques are gaining traction too. Closed-loop systems are being implemented to reuse materials. This approach minimizes waste but requires significant resources and planning to execute successfully. It raises questions about feasibility for smaller manufacturers. The pursuit of sustainability in the chemical sector shows promise, yet it still demands cautious navigation.

10 Best Innovations in the Chemical Manufacturing Industry

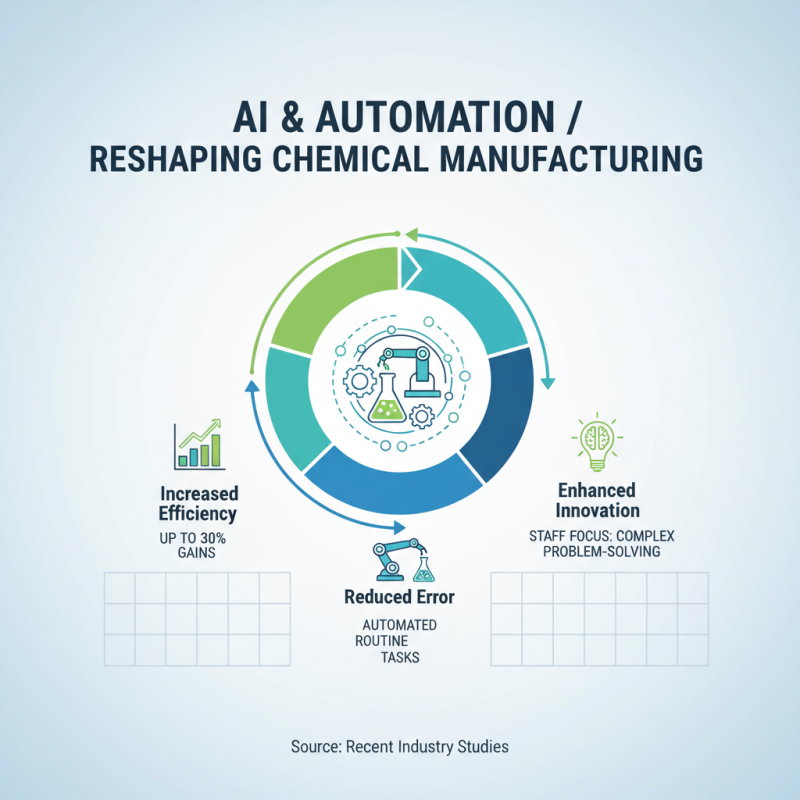

Integration of Automation and AI in Chemical Processes

The integration of automation and AI is reshaping the chemical manufacturing industry. Recent studies indicate that companies adopting these technologies saw efficiency gains of up to 30%. Automating routine tasks reduces human error. This allows staff to focus on complex problem-solving, which is essential in this intricate industry.

AI algorithms analyze massive datasets. They reveal patterns that humans might overlook. For example, predictive maintenance can decrease equipment downtime by up to 25%. However, this shift toward automation isn’t without challenges. Training workers to use new technologies effectively is critical, yet many companies struggle with employee resistance.

Moreover, the investment may seem hefty at first. Reports suggest that a full shift to integrated systems can cost millions. Smaller companies might find it hard to keep pace. The need for a skilled workforce capable of managing AI tools adds another layer of complexity. Thus, while automation and AI hold promise, the journey requires careful planning and meaningful investment in human capital.

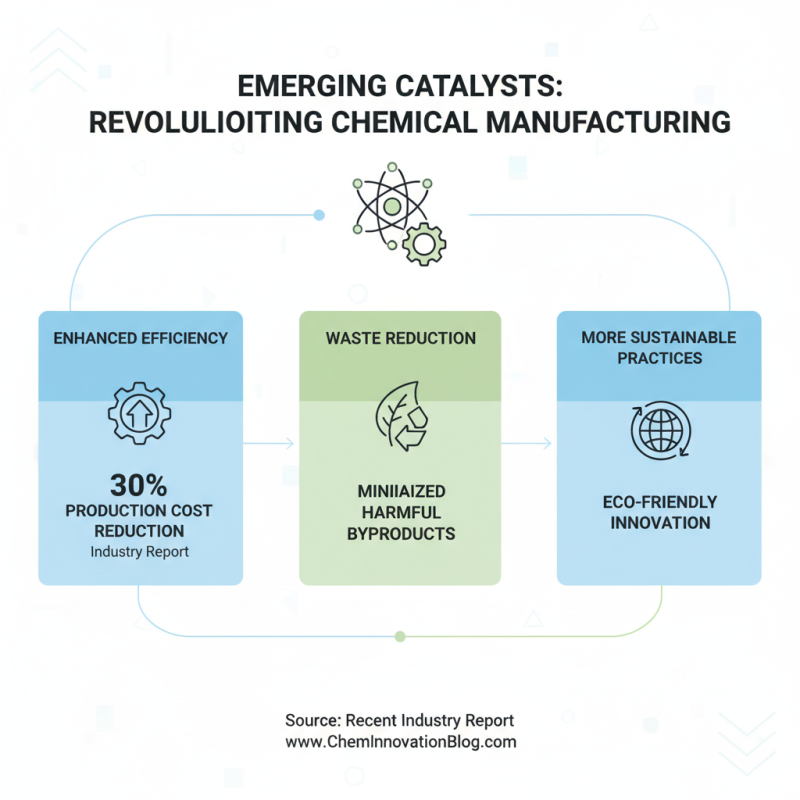

Emerging Catalysts: Enhancing Efficiency and Reducing Waste

Emerging catalysts are revolutionizing the chemical manufacturing industry. These innovative materials enhance efficiency while significantly reducing waste. According to a recent industry report, developing catalysts can cut production costs by 30%. Such advancements also minimize harmful byproducts, encouraging more sustainable practices.

In addition, the introduction of biocatalysts is a promising area. These catalysts can operate under milder conditions, reducing energy consumption by up to 50%. Moreover, biocatalysts are derived from renewable sources, aligning with the industry's shift towards sustainability. However, their higher initial costs may deter some manufacturers. It's crucial to weigh the long-term benefits against upfront investments.

Tips: Consider pilot projects to test new catalysts without a massive financial commitment. Collaborate with research institutions for access to emerging technologies. Staying informed about industry trends can guide better decision-making. Embracing change may require patience, yet innovation can lead to significant advancements in chemical manufacturing.

The Role of Biotechnology in Modern Chemical Solutions

Biotechnology has become a vital component in the chemical manufacturing industry. It offers innovative solutions that address environmental challenges. By harnessing natural processes, companies can develop sustainable products. This approach reduces waste and minimizes harmful emissions.

For instance, biocatalysts play a significant role in chemical reactions. They can replace traditional catalysts, which often require harsh conditions. This switch can lower energy consumption and improve efficiency. However, the technology is still evolving. Many firms face challenges in scaling up production while maintaining quality.

There's also the potential for bioplastics. These products can reduce dependence on fossil fuels. They are biodegradable, which addresses pollution concerns. Yet, the production processes are not yet perfect. Questions about sourcing raw materials and their ecological impact remain. Continuous reflection on these practices is crucial for future advancements.

Related Posts

-

How to Choose the Right Chemical Supply for Your Business Needs

-

How to Choose the Right Chemical Vendors for Your Business Needs in 2025

-

Top 10 Essential Chemicals in Chemistry You Need to Know

-

Why Are Chemical Raw Materials Essential for Modern Manufacturing Processes?

-

Top 10 Reagent Chemicals You Need for Your Laboratory Experiments

-

How to Choose the Right Chemical Company for Your Business Needs

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch