How to Choose the Right Chemical Manufacture Process for Your Needs?

Choosing the right chemical manufacture process can be daunting. According to Dr. Emily Carter, a leading expert in chemical engineering, "Selecting the right processes can dramatically affect quality and cost." Her insight highlights the importance of understanding your specific needs.

The world of chemical manufacture is complex and varied. Different processes can yield different results. Factors such as production scale, safety, and environmental impact must be considered carefully. Each decision shapes the final product and its market success.

Yet, it's easy to overlook critical details. Many companies rush through this choice, impacting efficiency. For instance, a decision that seems cost-effective may compromise product purity. Reflecting on these choices is vital for sustainable success in chemical manufacture.

Understanding Different Chemical Manufacturing Processes

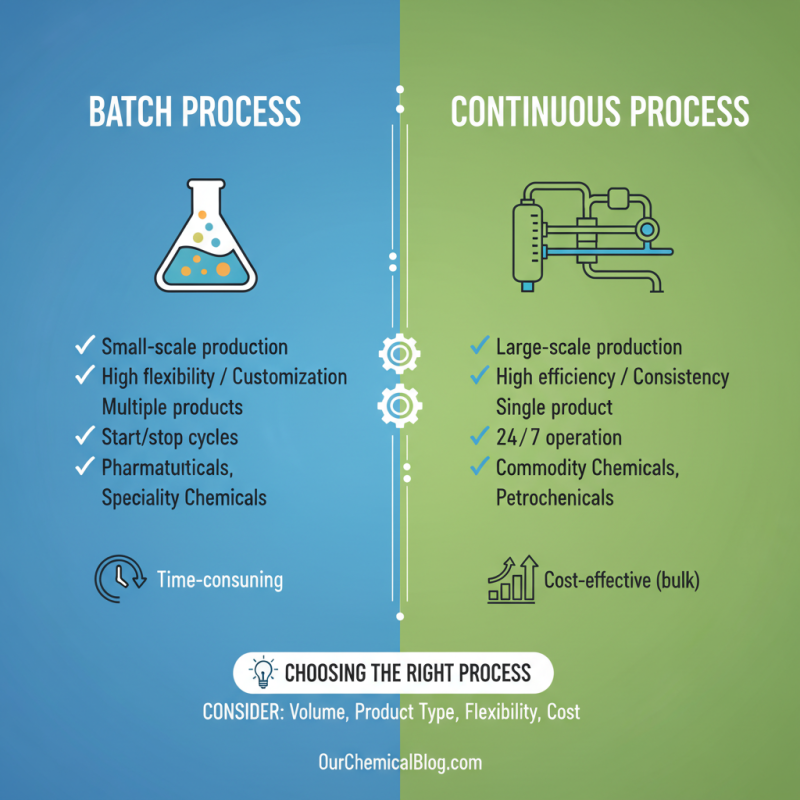

Choosing the right chemical manufacturing process requires a clear understanding of your specific needs. Different processes have unique characteristics, advantages, and limitations. Batch processes are ideal for small production runs. They allow flexibility and customization. Conversely, continuous processes are efficient for large scales. They enable consistent product quality.

When evaluating processes, consider factors like cost, scale, and desired product specification. A small change in process can lead to significant differences in yield and quality. Make sure to analyze the environmental impact as well.

Tips: Identify your priorities early. Is cost more critical than flexibility? Engaging with experts can provide valuable insights. Collect data on production rates and quality controls in various processes. Analyze this information to inform your decision. Recognizing the limitations of your knowledge can prompt further research. Never underestimate the value of pilot testing. It can reveal unforeseen issues.

Assessing Your Specific Chemical Production Requirements

When assessing your specific chemical production requirements, it’s essential to take a close look at your goals. What product do you want to create? What are the expected volumes? Understanding these factors is vital for choosing the right manufacturing process. Different processes have unique strengths and limitations. Make sure to align your needs with the capabilities of each method.

Evaluate the resources available to you. Do you have local materials that could influence your choice? For instance, proximity to raw materials can lower transportation costs. Additionally, consider the environmental implications of your process. Striving for a sustainable approach can save costs and enhance your brand's reputation.

**Tip:** Conduct a thorough feasibility study. This can help you identify challenges early. It’s also wise to consult with experts. Their insights can highlight what you might not see.

Be prepared to adapt your plans as you learn more. The initial ideas might not always work out as expected. Flexibility can lead to better long-term solutions. Remember, the best choice may not be the most obvious one. Stay open to new possibilities as your project evolves.

Evaluating Cost-Effectiveness of Manufacturing Options

When evaluating the cost-effectiveness of manufacturing options, several factors must be taken into account. Understanding the chemical processes involved is crucial. Each process has its own cost structure and requirements. You should analyze the raw materials, labor, and utility costs. A small change in any of these can significantly affect the overall expenses.

Tip: Gather multiple quotes from chemical suppliers. This allows for a comparative analysis of costs. Look for hidden fees as well. These can often inflate the final price.

It’s also important to consider scalability. Some processes may be cheaper for small batches but more expensive for larger scales. Reflect on your production goals. Do you plan to expand? If so, choosing a flexible manufacturing process may save money in the long run.

Tip: Think about energy consumption too. Highly efficient processes can reduce operational costs. Sometimes, the initial investment in technology pays off over time. Always weigh short-term savings against long-term benefits.

Cost-Effectiveness of Chemical Manufacturing Processes

Considering Environmental and Safety Regulations in Process Selection

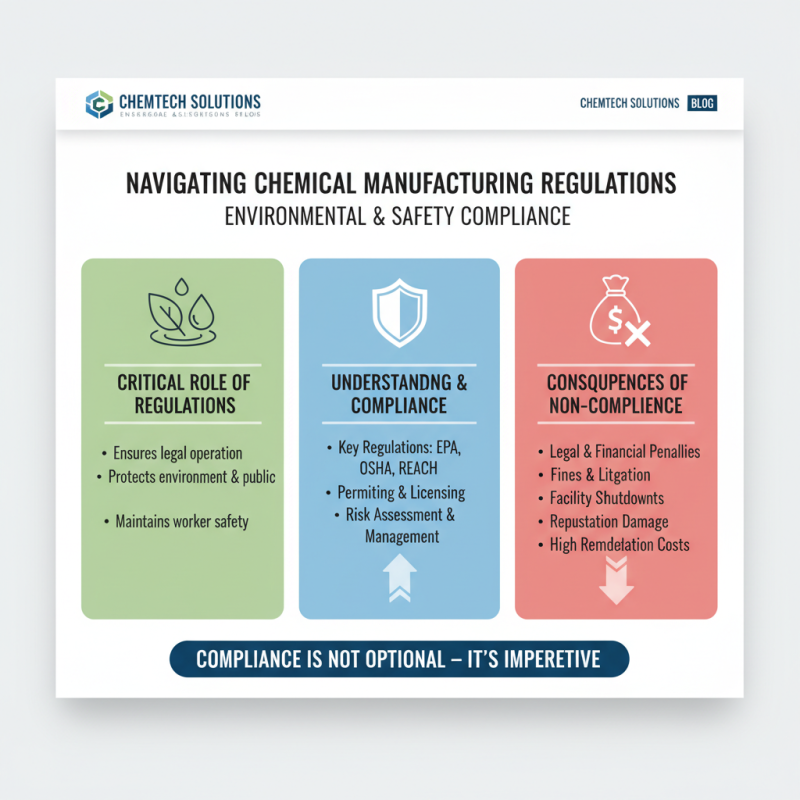

When selecting a chemical manufacturing process, environmental and safety regulations play a critical role. It is vital to understand these regulations to ensure compliance. Failing to do so can lead to legal trouble and financial losses. There can be significant costs associated with non-compliance, including fines and remediation efforts.

Consider the type of chemicals being produced. Some processes may generate more waste than others. This excess can impact both the environment and production costs. A process that appears efficient might not account for the waste generated. Is it truly sustainable? The balance between efficiency and environmental impact often needs more reflection.

In addition, safety measures must be put in place to protect workers and surrounding communities. Processes may pose risks that are not immediately obvious. Regular assessments are necessary to identify potential hazards. Create a culture of safety within the organization. Employees should feel empowered to speak up about safety issues. By prioritizing safety, the potential for accidents can significantly decrease.

Analyzing Scalability and Flexibility in Production Methods

When selecting a chemical manufacturing process, scalability and flexibility are key considerations. Industries report that over 60% of production methods face challenges in adapting to market changes. A scalable process means that as demand increases, production can grow without significant delays or costs. Flexibility allows manufacturers to adjust their operations quickly. For instance, batch production methods can be more adaptable for small runs compared to continuous processes.

Tips: Always assess your projected production volume. Are you prepared for fluctuations? If demand spikes, can your chosen process keep up?

Research shows that 70% of companies prioritize flexible manufacturing for niche products. This approach allows for quick changes in formulations or product designs. However, flexibility often comes with added complexity in logistics and supply chains. Not all processes are equipped for rapid changes, leading to potential downtime.

Tips: Evaluate your supply chain capabilities. Do you have the resources to switch suppliers quickly?

Ultimately, the right choice hinges on both current needs and future adaptability. Regularly revisiting your process choices can prevent stagnation. A flexible mindset is just as crucial as the manufacturing process itself.

How to Choose the Right Chemical Manufacture Process for Your Needs? - Analyzing Scalability and Flexibility in Production Methods

| Production Method | Scalability (1-5) | Flexibility (1-5) | Cost (per unit) | Lead Time (days) |

|---|---|---|---|---|

| Batch Process | 4 | 4 | $15 | 14 |

| Continuous Flow Process | 5 | 3 | $10 | 7 |

| Semi-Batch Process | 3 | 5 | $12 | 10 |

| Membrane Separation | 4 | 4 | $20 | 15 |

| Catalytic Process | 3 | 5 | $18 | 12 |

Related Posts

-

Top 10 Reagent Chemicals You Need for Your Laboratory Experiments

-

Top 10 Essential Chemicals in Chemistry You Need to Know

-

Why Are Chemical Raw Materials Essential for Modern Manufacturing Processes?

-

How to Choose the Right Chemical Supply for Your Business Needs

-

How to Choose the Right Chemical Vendors for Your Business Needs in 2025

-

10 Best Innovations in the Chemical Manufacturing Industry?

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch