How to Choose the Right Chemical Vendors for Your Business Needs in 2025

In an increasingly complex global market, selecting the right chemical vendors is paramount for businesses aiming to thrive in 2025 and beyond. Experts in the field emphasize the need for careful evaluation and strategic partnerships. As Dr. Emily Thompson, a leading authority on supply chain management in the chemical industry, aptly states, "The right chemical vendors do not just supply products; they provide essential support in innovation and sustainability."

With the landscape of the chemical market constantly evolving, businesses must prioritize vendors that align with their operational requirements and ethical standards. This entails scrutinizing potential partners for their compliance with safety regulations, reliability in delivery, and commitment to sustainable practices. Moreover, building a collaborative relationship with chemical vendors can lead to innovations that not only enhance product quality but also promote environmental responsibility.

In this guide, we will delve into the key considerations for choosing chemical vendors that will empower your business to meet its goals while navigating the challenges of the industry. By equipping yourself with the right knowledge, you can ensure that your selection process is both comprehensive and strategic, setting the foundation for long-term success.

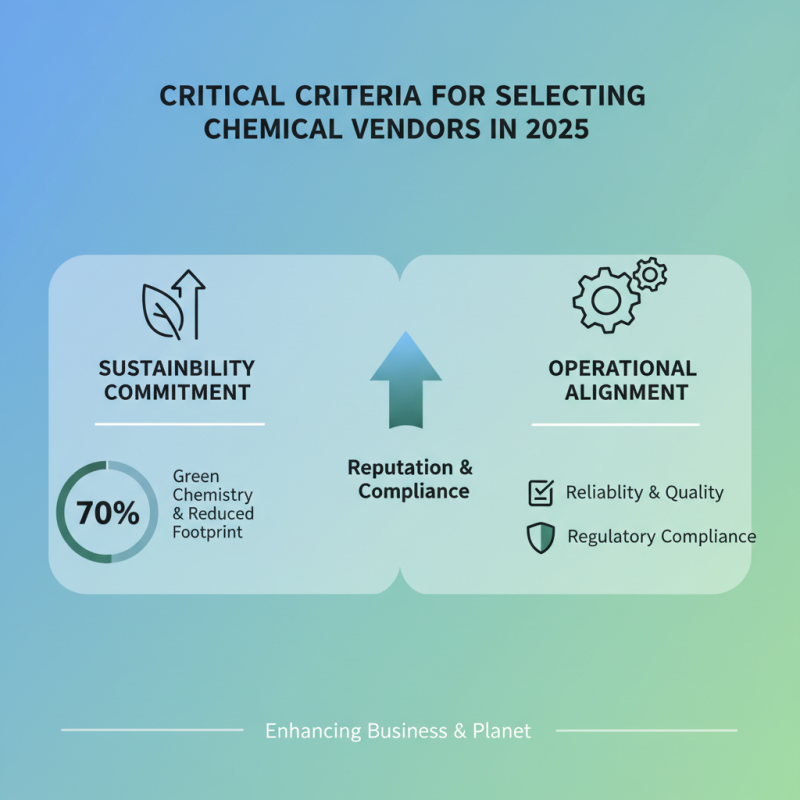

Identifying Key Criteria for Selecting Chemical Vendors in 2025

When selecting chemical vendors in 2025, businesses must consider several critical criteria to ensure they align with their operational needs and sustainability goals. First, the vendor's commitment to sustainability and eco-friendly practices is paramount. According to a report by the Chemical Industry Association, approximately 70% of companies in the chemical sector are implementing sustainability initiatives in response to consumer demand and regulatory pressure. Vendors that prioritize green chemistry and reduced environmental footprints can significantly enhance a business's reputation and compliance standing.

Another essential criterion is the vendor's experience and expertise in the specific chemicals required. Businesses should evaluate the vendor's track record, industry certifications, and ability to meet specific regulatory requirements. A study by the American Chemical Society indicates that vendors with extensive expertise can provide better product quality and reliability, ultimately influencing overall business performance.

**Tips:**

- Always request references and case studies from potential vendors to validate their claims of expertise and reliability.

- Assess the vendor’s supply chain stability and ability to adapt to unforeseen circumstances, as this can affect your operational continuity.

Lastly, technology integration should be evaluated. Vendors that leverage advanced technologies in production and logistics can offer significant advantages in efficiency and cost. A recent survey by the Global Chemical Markets highlighted that companies utilizing digital solutions reported a 25% improvement in operational efficiency. Selecting a vendor who embraces innovation can provide a competitive edge in today’s fast-paced market.

Evaluating Vendor Reputation: Importance of Industry Certifications and Awards

When selecting chemical vendors for your business, evaluating their reputation is paramount. One of the most effective ways to gauge this reputation is through their industry certifications and awards. Certifications often serve as a testament to a vendor's commitment to safety, quality, and environmental standards. For instance, ISO certifications indicate that a vendor adheres to international quality management systems, which can significantly reduce risk in your supply chain. Additionally, industry-specific certifications can demonstrate a vendor’s expertise and reliability in handling specific types of chemicals, ensuring they are equipped to meet your business needs.

Awards and recognitions also play a crucial role in vendor evaluation. These accolades can reflect a vendor’s standing within the industry and their track record of performance. Engaging with vendors that have been recognized for excellence in customer service or sustainability practices not only reflects their ability to comply with regulations but also their capacity for innovation. By prioritizing vendors with solid reputations backed by certifications and industry awards, businesses can foster partnerships that enhance operational efficiency and contribute to long-term success.

Analyzing Supply Chain Reliability: Metrics to Consider for Vendor Selection

When selecting chemical vendors for your business in 2025, analyzing supply chain reliability becomes paramount. A key metric to consider is the vendor's historical delivery performance. Tracking on-time delivery rates can provide insight into their consistency and ability to meet your production schedules. Additionally, evaluate their lead times and flexibility in responding to urgent requests; vendors who can adapt quickly to changes in demand are invaluable.

Another important aspect to focus on is the vendor's quality assurance processes. Investigate their certification standards, testing protocols, and quality control measures. Reliable vendors should demonstrate a commitment to maintaining high product quality through rigorous testing and adherence to industry regulations. Furthermore, assessing the vendor's financial stability can reduce risks associated with unexpected disruptions in supply. A financially secure vendor is more likely to withstand market fluctuations and maintain a steady supply chain, ensuring that your business can operate smoothly.

Supply Chain Reliability Metrics for Chemical Vendors in 2025

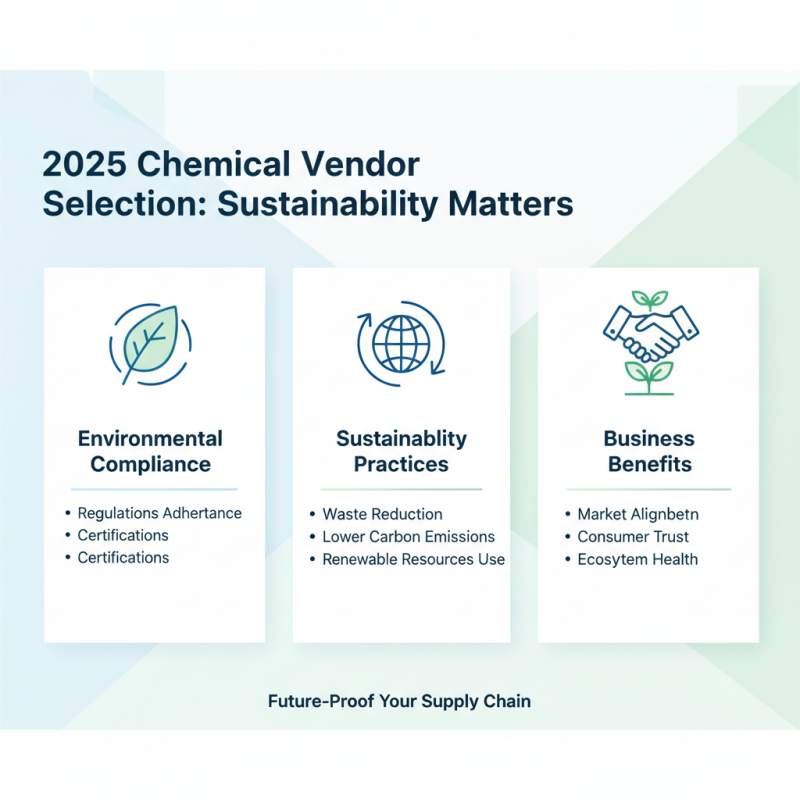

Assessing Environmental Compliance and Sustainability Practices in Chemistry

When selecting chemical vendors in 2025, understanding their environmental compliance and sustainability practices is paramount. In today's climate-conscious market, businesses are increasingly held accountable for their supply chain choices. Vendors that prioritize sustainability not only contribute to a healthier ecosystem but also align with the values of consumers who favor environmentally responsible products. Evaluating a vendor’s commitment to reducing waste, lowering carbon emissions, and utilizing renewable resources can provide crucial insights into their operational integrity.

Furthermore, it is essential to assess the vendor's adherence to regulations and standards that govern environmental practices in the chemistry industry. Compliance with local and global environmental regulations ensures that the vendor operates within legal frameworks, thus safeguarding your business from potential liabilities. Engaging with vendors who have transparent reporting on their sustainability efforts, such as greenhouse gas emissions or hazardous waste management, allows businesses to make informed decisions. Collaborating with environmentally responsible vendors not only enhances corporate reputation but also fosters innovation in sustainable chemical solutions, paving the way for a greener future in the industry.

Cost-Benefit Analysis: Balancing Quality and Price in Vendor Relationships

When selecting chemical vendors, a critical factor to consider is the cost-benefit analysis, particularly when balancing quality against price. According to a report from the National Association of Chemical Distributors (NACD), businesses that prioritize long-term partnerships with suppliers often see a return on investment of 20% or more due to enhanced product quality and service reliability. This suggests that while lower-priced options may seem financially appealing initially, they can often result in higher costs down the line due to inferior quality, increased operational risks, and potential compliance issues.

Furthermore, a study conducted by Market Research Future indicates that companies that evaluate the total cost of ownership (TCO) during the vendor selection process achieve an average of 15% savings over a five-year period. This approach considers not just the upfront costs but also potential additional expenses related to subpar materials, lost production time, and inadequate supplier support. By integrating a thorough cost-benefit analysis into the decision-making process, businesses can forge vendor relationships that not only meet immediate budget constraints but also align with their long-term strategic goals, ensuring operational efficiency and product excellence.

How to Choose the Right Chemical Vendors for Your Business Needs in 2025 - Cost-Benefit Analysis: Balancing Quality and Price in Vendor Relationships

| Vendor Rating | Quality Score | Price per Unit ($) | Delivery Time (days) | Customer Support Rating |

|---|---|---|---|---|

| A | 9.5 | 150 | 5 | 8.0 |

| B | 8.0 | 120 | 3 | 7.5 |

| C | 7.5 | 100 | 7 | 9.0 |

| D | 6.0 | 80 | 10 | 6.0 |

| E | 8.5 | 130 | 4 | 8.5 |

Related Posts

-

How to Choose the Right Chemical Supply for Your Business Needs

-

Top 10 Essential Chemicals in Chemistry You Need to Know

-

Why Are Chemical Raw Materials Essential for Modern Manufacturing Processes?

-

Top 10 Reagent Chemicals You Need for Your Laboratory Experiments

-

How to Choose the Right Chemical Company for Your Business Needs

-

How to Source Quality Chemical Raw Materials for Your Business Needs

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch