2025 How to Source High-Quality Plastic Raw Materials Efficiently

In an era where sustainability and efficiency are paramount, sourcing high-quality plastic raw materials has become a critical focus for manufacturers across various industries. As noted by Dr. Emily Carter, a leading expert in polymer science, “The future of our industry hinges on our ability to innovate while ensuring that the plastic raw materials we use are both sustainable and of the highest quality.” This statement underscores the dual challenge faced by companies: to meet stringent quality standards while also adhering to environmentally responsible practices.

As the demand for high-quality plastic raw materials continues to rise, businesses must navigate a complex landscape of suppliers and sourcing strategies. Identifying reliable sources that provide consistent quality and sustainability is essential for maintaining competitive advantage. Moreover, with advances in technology and a growing emphasis on eco-friendly materials, companies have the opportunity to explore alternative sources that align with both their operational goals and environmental commitments. This careful balancing act is crucial for the future viability of the plastic industry and the successful implementation of new materials in production processes.

Ultimately, sourcing high-quality plastic raw materials efficiently is not only about cost reduction but also about fostering innovation and striving for a sustainable future in manufacturing. The choices made today will shape the landscape of the industry for years to come, making it imperative for stakeholders to remain informed and proactive in their sourcing strategies.

Understanding the Global Plastic Raw Materials Market Dynamics in 2025

In 2025, understanding the dynamics of the global plastic raw materials market is crucial for businesses seeking to source high-quality materials effectively. The market has been evolving rapidly due to factors such as changing consumer preferences, regulatory pressures, and advancements in material science. As sustainability becomes a priority, manufacturers are increasingly looking for recycled materials and sources that adhere to eco-friendly standards. A deep knowledge of market trends and emerging suppliers will empower businesses to make informed sourcing decisions.

**Tips:** When sourcing plastic raw materials, it’s essential to establish strong relationships with suppliers. This not only ensures a steady supply but also facilitates better negotiation terms. Attend industry events and trade shows to network with potential suppliers and stay updated on the latest innovations in materials.

Moreover, leveraging data analytics can significantly enhance sourcing strategies. By analyzing market trends and supplier performance, companies can identify opportunities for cost savings and improvements in quality. Implementing a just-in-time inventory system can also reduce excess stock and optimize processes, ensuring that businesses stay agile in a competitive market.

Key Criteria for Assessing the Quality of Plastic Raw Materials

When sourcing high-quality plastic raw materials, it's crucial to establish clear criteria for assessing quality that can significantly impact production processes and end products. The first key aspect to consider is the material's physical properties, such as density, tensile strength, and thermal stability. These attributes directly affect the performance of the final product, making it essential to source materials that meet specific standards based on intended applications. Depending on the end use, materials should demonstrate adequate durability and resistance to environmental factors like UV exposure and temperature fluctuations.

Another important criterion is the consistency of the material's composition. High-quality raw materials should have uniform characteristics across batches to ensure predictable processing behavior and product performance. This consistency can typically be verified through certification from reliable suppliers or laboratory testing that includes analyses of additives and fillers. Furthermore, assessing the supplier's quality control processes is vital; suppliers that adhere to stringent quality management systems are more likely to provide materials that meet the required specifications, reducing waste and enhancing overall manufacturing efficiency.

2025 How to Source High-Quality Plastic Raw Materials Efficiently

Evaluating Sustainable Sourcing Practices for Plastic Raw Materials

Sustainable sourcing practices for plastic raw materials are becoming increasingly critical in an era where environmental concerns take precedence. Companies are now evaluating their supply chains to minimize ecological footprints and promote the responsible use of resources. A key aspect of sustainable sourcing involves selecting suppliers who prioritize environmentally friendly extraction methods and utilize recycled materials. By adopting a circular economy approach, businesses can ensure that their raw materials not only meet quality standards but also contribute to waste reduction and resource conservation.

Evaluating the sustainability of sourcing practices also entails assessing the life cycle impact of plastic raw materials. This includes understanding the environmental effects of production processes, transportation, and eventual disposal. Companies can set benchmarks for sustainability by analyzing factors such as carbon emissions, water usage, and the overall ecological impact of their entire supply chain. Engaging in transparent collaboration with suppliers and industry stakeholders can help identify innovative solutions and best practices, driving progress toward a more sustainable plastic industry. Implementing these evaluations not only enhances corporate responsibility but also meets the growing demand from consumers for environmentally conscious products.

Utilizing Technology and Innovation to Streamline Sourcing Processes

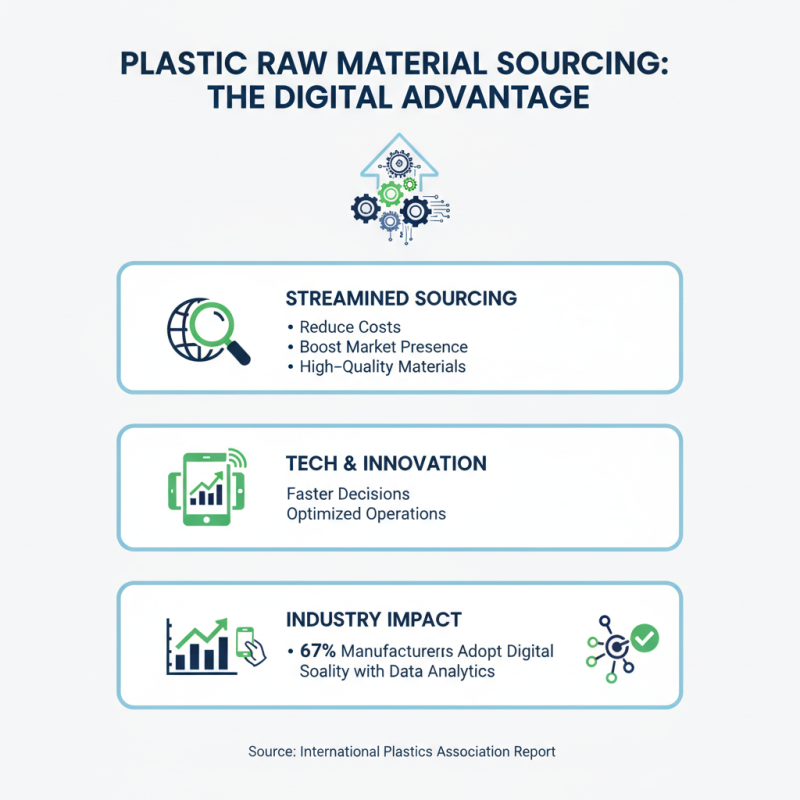

In today's competitive landscape, sourcing high-quality plastic raw materials efficiently is crucial for manufacturers aiming to reduce costs and boost their market presence. Leveraging technology and innovation in sourcing processes not only helps streamline operations but also enables businesses to make informed decisions more swiftly. According to a report by the International Plastics Association, up to 67% of manufacturers have adopted digital solutions in their sourcing strategies, and those utilizing advanced data analytics have reported significant improvements in supply chain transparency and material quality assessment.

Incorporating innovative technologies such as AI and machine learning can enhance predictive analytics, enabling businesses to anticipate fluctuations in raw material availability and price variations. By utilizing these technologies, companies can better identify reliable suppliers and optimize their inventory management. A study by McKinsey indicated that companies actively employing digital sourcing frameworks could achieve up to a 30% reduction in procurement costs, creating opportunities for reinvestment into other critical areas of the business.

Tips: Foster collaborative partnerships with technology providers to stay updated on emerging tools that can optimize the sourcing process. Additionally, consider utilizing supplier scorecards to evaluate performance based on quality and delivery metrics, allowing for more informed decision-making. Engaging in continuous learning about market trends will also empower sourcing teams to adapt quickly and effectively to industry changes.

Identifying Reliable Suppliers and Building Strategic Partnerships in 2025

In 2025, sourcing high-quality plastic raw materials will increasingly rely on identifying reliable suppliers and establishing strategic partnerships. The first step in this process is evaluating potential suppliers based on their track record, certifications, and production capabilities. Companies should look for suppliers with extensive experience in the industry and those who adhere to the highest quality standards. Conducting thorough due diligence, including factory visits and quality inspections, can help organizations assess the authenticity and reliability of potential partners.

Building strategic partnerships will be essential for ensuring a consistent supply of quality materials. Collaborating with suppliers can lead to innovations in material technology and improved production processes. By forming long-term relationships rooted in trust and mutual benefit, companies can negotiate better terms, improve delivery timelines, and gain access to exclusive product lines. Establishing clear communication channels and aligning on objectives will further enhance these partnerships, enabling both parties to adapt to market changes and demand fluctuations more efficiently.

Related Posts

-

Top 10 Bulk Chemicals You Need to Know for Your Industry

-

Top 10 Essential Chemicals in Chemistry You Need to Know

-

Unlocking the Future: Top 2025 Essential Cosmetic Raw Materials Trends

-

Top 10 Reagent Chemicals You Need for Your Laboratory Experiments

-

How to Choose the Right Chemical Company for Your Business Needs

-

2025 How to Optimize Reagent Manufacturing for Maximum Efficiency

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch