How to Optimize Production Efficiency in the Chemical Manufacturing Industry?

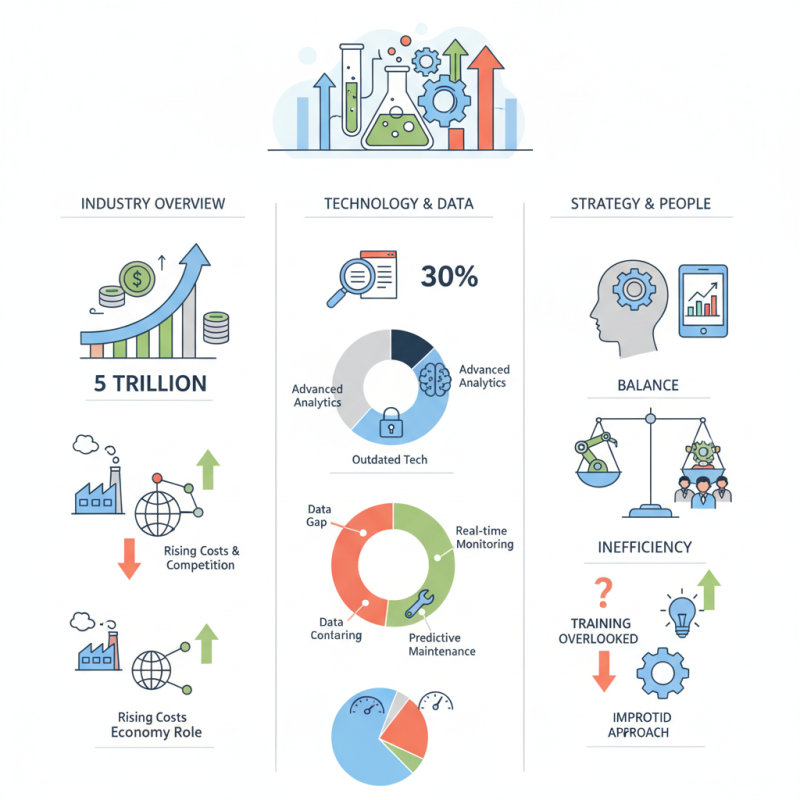

The chemical manufacturing industry plays a critical role in the global economy. In 2022, this industry generated over $5 trillion in revenue. Amid rising costs and increasing competition, optimizing production efficiency is more vital than ever. Many companies still rely on outdated technologies. This can hinder growth and waste valuable resources.

According to a report by McKinsey, firms that embrace advanced analytics can improve efficiency by up to 30%. However, only 15% of companies in the chemical sector have implemented these technologies effectively. There remains a significant gap in understanding how to leverage data effectively. Improving real-time monitoring and predictive maintenance could yield substantial benefits.

Challenges persist in adopting best practices. Many companies often overlook workforce training in the push for automation. This can lead to inefficiencies and errors. A balanced approach that incorporates both technology and human expertise is crucial to driving better results in the chemical manufacturing industry. The potential for improvement is immense, yet many organizations need to reflect on their current strategies to realize this potential fully.

Understanding Production Efficiency in Chemical Manufacturing

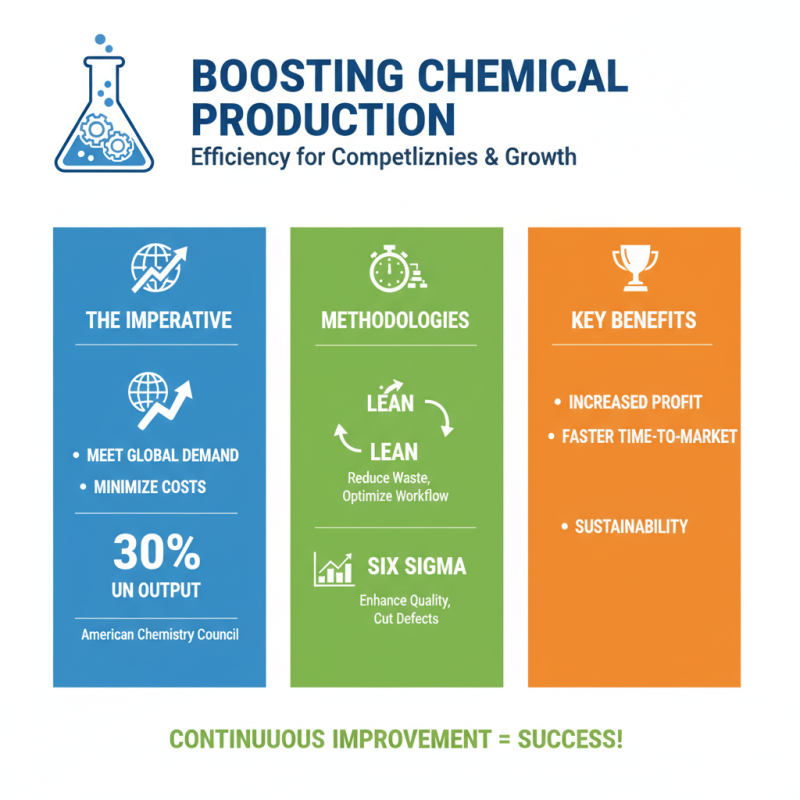

Production efficiency in the chemical manufacturing sector is crucial for competitiveness. According to the American Chemistry Council, optimizing production processes can lead to increases in output by up to 30%. This is significant for companies aiming to meet rising global demands while minimizing costs. Focusing on continuous improvement methodologies, such as Lean and Six Sigma, can enhance workflow and reduce waste.

Data from the National Association of Chemical Distributors indicates that nearly 70% of chemical manufacturers struggle with production downtime. Often, this is due to outdated equipment or ineffective maintenance strategies. Regular audits of machinery, combined with predictive maintenance, can mitigate these challenges. Identifying bottlenecks in production processes requires time and intuition.

Additionally, workforce training cannot be overlooked. Engaging employees in efficiency programs leads to better outcomes. Employees often see potential areas for improvement that management may miss. However, it can be a challenge to motivate teams consistently. Investing in training resources is essential, but the initial costs can be a barrier. Balancing financial constraints and efficiency goals remains a delicate task for many firms.

Identifying Key Performance Indicators (KPIs) for Optimization

In the chemical manufacturing industry, identifying the right KPIs is crucial for optimization. Relevant KPIs help track production efficiency and identify bottlenecks. Common metrics include production yield, cycle time, and energy consumption. It's essential to ensure these indicators align with overall production goals.

Monitoring production yield allows manufacturers to assess the quality of their output. A low yield might indicate issues like equipment malfunction or raw material impurities. Cycle time can reveal delays in the production process. If cycle times are consistently high, it may signal inefficiencies that require attention.

Energy consumption is another critical KPI. High energy use can drive up costs and indicates waste. Manufacturers must analyze this data regularly to identify opportunities for improvement. However, relying solely on KPIs can lead to a narrow focus. Sometimes, qualitative factors also impact production efficiency. Balancing hard data with team feedback could reveal hidden challenges.

Implementing Lean Manufacturing Principles in Production Processes

Implementing lean manufacturing principles can significantly enhance production efficiency in the chemical manufacturing industry. Lean principles focus on minimizing waste while maximizing productivity. This approach helps streamline processes and reduces unnecessary steps.

For instance, by reorganizing production layouts, manufacturers can improve flow and decrease lead times.

However, adopting lean practices isn't without challenges. Some teams may resist changes due to fear of uncertainty. There might be initial drops in efficiency as workers adapt to new systems. It’s crucial to offer training and involve employees in the transition. Communication is key to mitigating resistance. Engaging staff fosters a culture of continuous improvement, but it requires patience.

Incorporating tools such as value stream mapping can identify areas for waste reduction. This visual representation highlights inefficiencies, enabling targeted improvements. Yet, careful analysis is necessary; not all changes will yield immediate benefits. Evaluating outcomes creates opportunities for reflection and adjustment. Lean isn’t a one-size-fits-all solution; it must be tailored to each unique operation.

Utilizing Technology and Automation to Enhance Output

In the chemical manufacturing industry, technology and automation play a significant role in optimizing production efficiency. According to recent reports, companies utilizing advanced automation can increase production output by up to 30%. This is achieved through reduced human error and faster processing times. Moreover, integrating IoT devices enables real-time monitoring. This not only enhances safety but also allows for predictive maintenance, minimizing downtime.

Tips: Consider investing in AI-driven software for better data analysis. These tools can forecast demand trends, helping factories adjust production schedules. Regular training for staff on new technologies is crucial. The industry sometimes witnesses resistance to change, impacting operational flow.

Automation also brings challenges. Transitioning to automated systems can require an upfront cost. Small chemical plants may find this investment daunting. Additionally, workforce fears about job security can hinder smooth implementation. Engaging employees in the transition process can mitigate these issues. Open dialogue promotes acceptance and eases the shift towards technology.

Training and Development for Workforce Efficiency Improvement

In the chemical manufacturing industry, workforce training plays a crucial role in optimizing production efficiency. Employees must understand complex processes and safety protocols. Regular training sessions enhance skill levels and boost confidence. Workshops allow workers to learn best practices, but they can also highlight gaps in knowledge.

Hands-on training is essential. Workers gain practical experience, which helps refine their techniques. However, not every session is effective. Sometimes, workers may resist new methods or struggle to adapt. These challenges can hinder progress. Encouraging open dialogue about these issues is vital for improvement.

Continuous development should involve feedback mechanisms. Employees should feel comfortable sharing their thoughts on training programs. This creates a cycle of growth. By addressing weaknesses, the workforce becomes more efficient. Investing in skill development is not enough alone; reflecting on its effectiveness is equally important.

Related Posts

-

Top 10 Essential Chemicals in Chemistry You Need to Know

-

Why Are Chemical Raw Materials Essential for Modern Manufacturing Processes?

-

How to Choose the Right Chemical Vendors for Your Business Needs in 2025

-

Top 10 Reagent Chemicals You Need for Your Laboratory Experiments

-

How to Choose the Right Chemical Company for Your Business Needs

-

How to Choose the Right Chemical Supply for Your Business Needs

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch