2025 How to Optimize Reagent Manufacturing for Maximum Efficiency

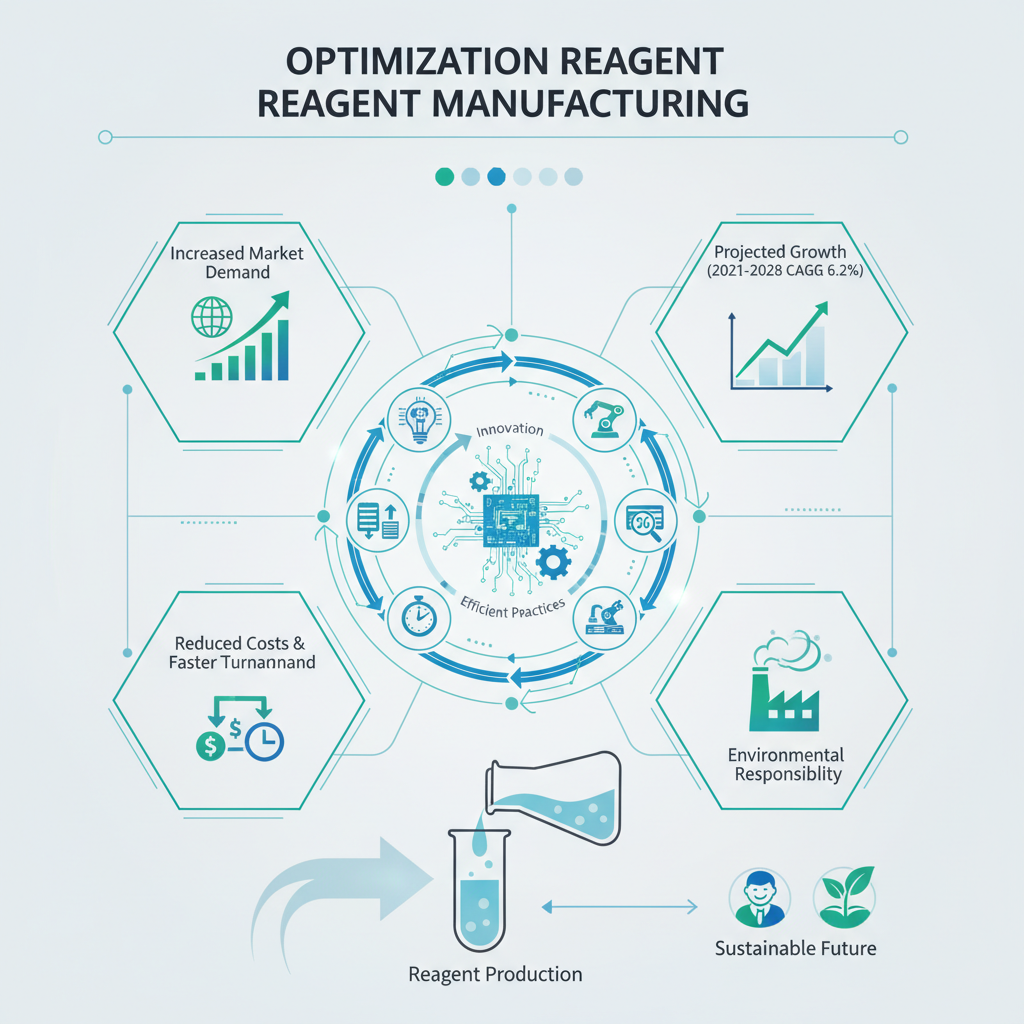

In the rapidly evolving landscape of the global economy, optimizing reagent manufacturing has become paramount for companies striving for maximum efficiency. As market demands escalate, the reagent manufacturing sector is projected to experience significant growth, with a report by Grand View Research indicating a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028. This underscores the necessity for manufacturers to streamline their processes and enhance productivity to remain competitive.

According to Dr. Emily Carter, a recognized expert in reagent manufacturing, "The future of chemical production lies in our ability to harness both innovative technologies and efficient practices." Her insights emphasize that integrating advanced manufacturing techniques can lead to reduced costs and improved turnaround times, ultimately benefiting both manufacturers and end-users. As the industry faces increased scrutiny regarding sustainability, optimizing reagent manufacturing processes not only addresses economic efficiency but also environmental responsibility, paving the way for a more sustainable future.

In this context, the focus of this paper is to explore various strategies for enhancing operational efficiency in reagent manufacturing, leveraging data-driven insights and expert opinions to provide a comprehensive framework for industry stakeholders.

Strategies for Streamlining Reagent Manufacturing Processes

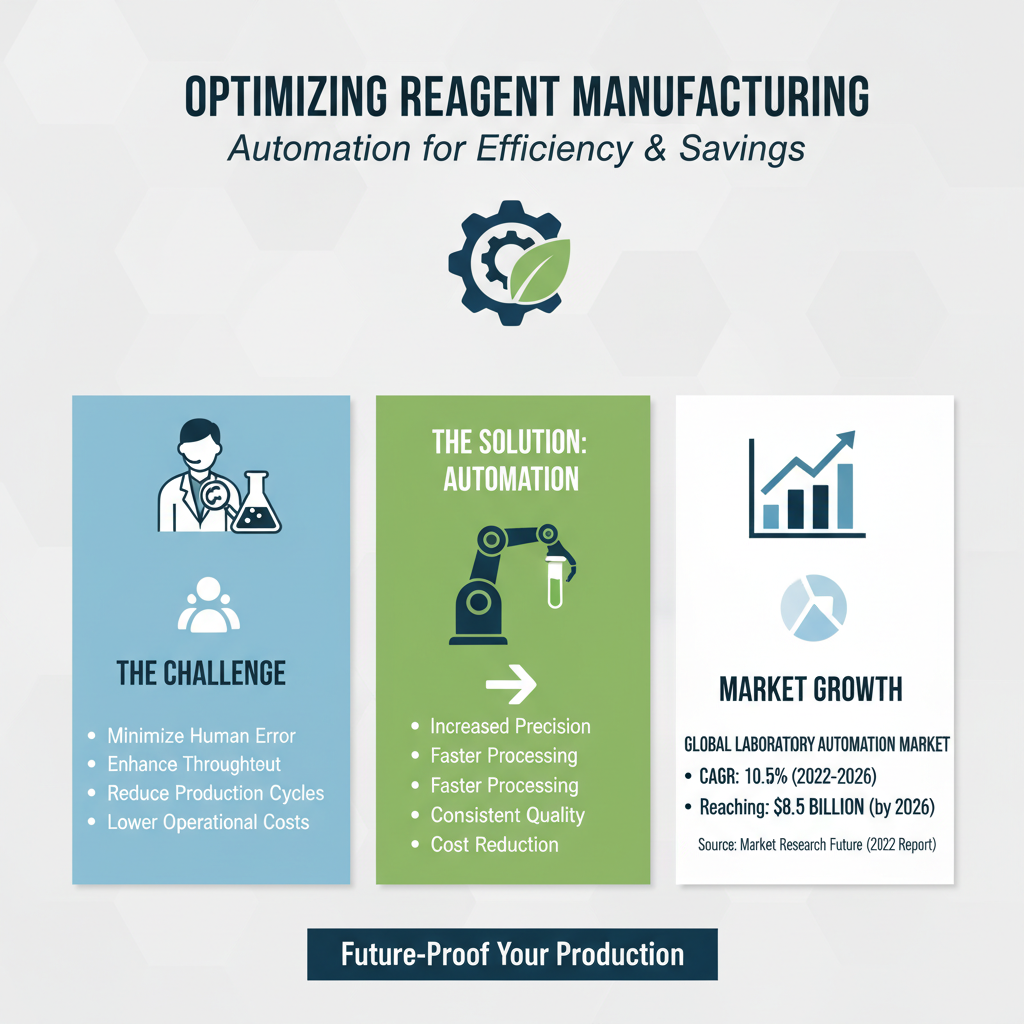

Optimizing reagent manufacturing is crucial for achieving maximum efficiency in the chemical and pharmaceutical industries. One effective strategy is the implementation of automation technologies. According to a 2022 report from Market Research Future, the global laboratory automation market is projected to grow at a CAGR of 10.5%, reaching USD 8.5 billion by 2026. By integrating automation into manufacturing processes, companies can minimize human error, enhance throughput, and reduce production cycle times, ultimately leading to lower operational costs.

Another vital strategy involves adopting lean manufacturing principles. The 2021 Lean Reagent Manufacturing Study revealed that organizations employing lean methodologies could reduce waste by up to 25% and improve overall production efficiency by 15%. This approach focuses on continuous improvement and value stream mapping, allowing manufacturers to identify and eliminate non-value-adding activities in their reagent production processes. By fostering a culture of efficiency and utilizing data-driven decision-making, companies can streamline operations and respond more swiftly to market demands, thereby achieving significant competitive advantages.

Technological Innovations for Enhanced Efficiency in Reagent Production

In the realm of reagent manufacturing, technological innovations play a pivotal role in enhancing efficiency and optimizing production processes. The progress in automation and data analytics allows companies to streamline their operations, reduce waste, and improve yield. By integrating advanced methodologies such as artificial intelligence and machine learning into their processes, manufacturers can refine their workflows, leading to faster turnaround times and cost savings. For instance, predictive analytics can help anticipate equipment failures, allowing for proactive maintenance and minimal downtime.

Moreover, innovations in material science are transforming the production landscape, particularly in the development of more efficient catalysts and reaction conditions. The shift towards greener chemistry not only meets regulatory requirements but also appeals to environmentally conscious consumers. Advances in techniques, such as microfluidics, enable more precise control over reaction conditions, further enhancing product quality. As the Grignard reagents market and the electrophoresis reagents market expand significantly, staying ahead through technological advancements will be essential for manufacturers looking to capitalize on growth opportunities in the evolving chemical industry.

Quality Control Measures to Optimize Reagent Manufacturing Output

To optimize reagent manufacturing output, implementing robust quality control measures is crucial. According to a report by BioIndustry Association (BIA), businesses that invest in quality control can reduce production errors by up to 30%, significantly impacting overall efficiency. By establishing strict quality benchmarks and adhering to protocols like Good Manufacturing Practices (GMP), manufacturers can ensure that their reagents meet the necessary standards consistently, thereby minimizing waste and maximizing resource utilization.

Another key aspect is the integration of automation in quality control processes. A study by the International Society for Pharmaceutical Engineering (ISPE) highlights that automation can enhance the accuracy of testing protocols, reducing manual errors by approximately 25%. Moreover, automation allows for real-time monitoring of the production environment, enabling quick corrective actions that help maintain product quality. This proactive approach not only accelerates the manufacturing cycle but also reinforces the reliability of output, ensuring that manufacturers remain competitive in a rapidly evolving market.

Sustainable Practices in Reagent Production for Long-Term Efficiency

Sustainable practices in reagent production are increasingly critical as industries strive for long-term efficiency while minimizing environmental impact. According to a recent report by the Chemical and Engineering News, the global chemical industry can reduce its carbon footprint by up to 20% through innovative manufacturing techniques and sustainable sourcing of materials. By adopting greener practices such as using renewable energy sources and implementing waste reduction methods, companies not only enhance their efficiency but also improve their market position as environmentally responsible entities.

Tip: Evaluate your supply chain for opportunities to integrate sustainable materials. For instance, using bio-based solvents or by-products from other processes can significantly lower environmental impact while maintaining quality.

Furthermore, investing in advanced technologies such as artificial intelligence and automation can streamline reagent production processes. The Allied Market Research indicates that automation in chemical manufacturing can increase productivity by up to 30%, reducing labor costs and minimizing human error. This efficiency translates directly into less resource waste and higher overall output, reinforcing the case for sustainable modernization of production facilities.

Tip: Regularly train staff on the latest technological advancements to ensure efficient use of new systems, maximizing both productivity and sustainability in your operations.

Optimization of Reagent Manufacturing for Maximum Efficiency

Workforce Training and Development to Improve Production Efficiency

Workforce training and development play a pivotal role in optimizing reagent manufacturing processes for maximum efficiency. According to a report by the National Institute of Standards and Technology (NIST), companies that invest in employee training see a productivity increase of up to 20%. This significant enhancement is particularly crucial in the reagent manufacturing sector, where precision and speed directly impact product quality and operational costs.

Moreover, a study conducted by the American Society for Manufacturing Engineering (ASME) showed that organizations with robust training programs have a 30% higher retention rate for skilled workers. This retention translates to a more experienced workforce that can effectively streamline production processes, reducing the time required for onboarding new employees. Implementing continuous education initiatives, such as workshops on advanced manufacturing techniques and safety protocols, further empowers employees, fostering a culture of innovation and efficiency that is essential for meeting the increasing demand in the reagent market.

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch