How to Source Quality Chemical Raw Materials for Your Business Needs

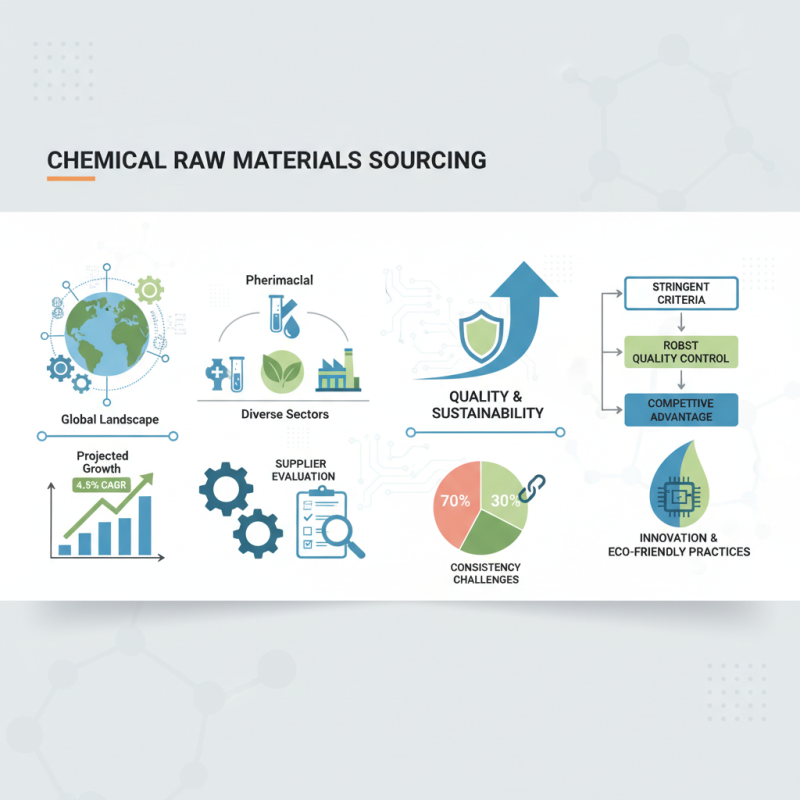

In the global landscape of manufacturing and production, sourcing quality chemical raw materials has become a pivotal focus for businesses striving for efficiency and sustainability. According to a report by the International Council of Chemical Associations (ICCA), the global chemical industry is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2020 to 2025, underscoring the increasing demand for high-quality chemical raw materials across diverse sectors, including pharmaceuticals, agrochemicals, and manufacturing. As industries ramp up efforts towards innovation and eco-friendly practices, the importance of sourcing quality materials cannot be overstated.

Navigating the complexities of sourcing chemical raw materials involves understanding not only the quality and purity of the substances but also the reliability and reputation of suppliers. The chemical industry is characterized by a vast array of suppliers, each offering varied levels of quality, and as highlighted in the latest market analysis by Deloitte, a staggering 70% of companies report difficulties in ensuring the consistent quality of their raw materials. This makes it essential for businesses to implement stringent criteria when evaluating suppliers and to establish robust quality control measures. In an era where sustainability and compliance are imperative, the ability to source quality chemical raw materials serves as a significant competitive advantage.

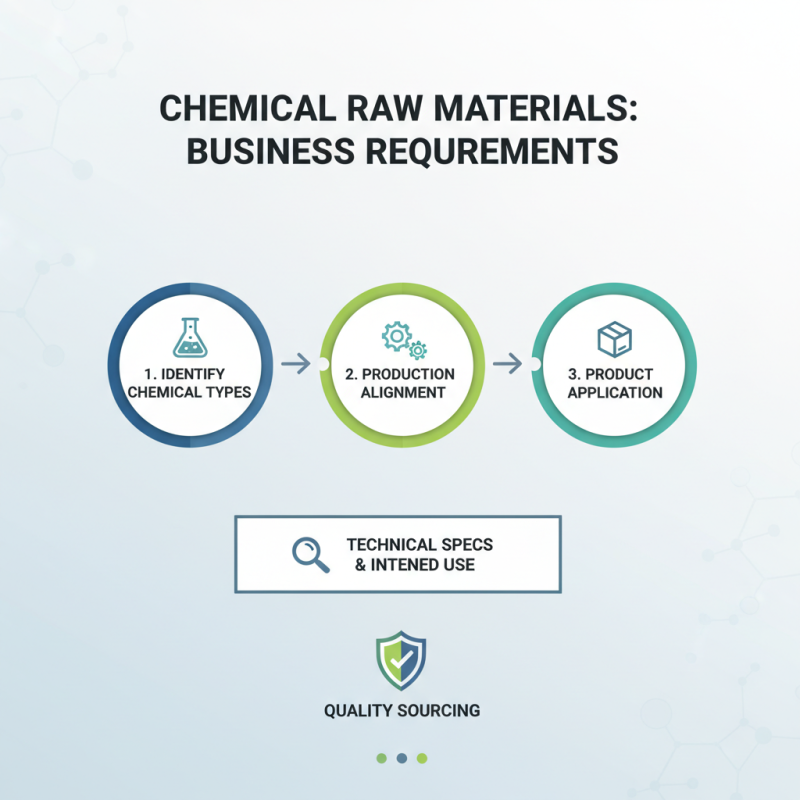

Identifying Your Business Requirements for Chemical Raw Materials

Identifying your business requirements for chemical raw materials is a crucial step in ensuring your operations run smoothly. To begin with, you should clearly outline the specific types of chemicals you need based on your production processes. This involves understanding both the technical specifications of the materials and the intended applications in your products. Having a thorough grasp of these details will help in sourcing high-quality materials that meet your exact needs.

**Tips:** Start by conducting a needs assessment within your team, involving key stakeholders who understand the manufacturing process. This collaborative approach can reveal nuanced requirements that may not be immediately obvious, ensuring that you cover all bases.

Next, consider your budget and the potential for scalability. While quality is paramount, understanding how much you can invest in raw materials will guide your sourcing decisions. This includes evaluating whether you will need to increase quantities in the future and how that may affect pricing.

**Tips:** Always source from multiple suppliers to mitigate risk and gain competitive pricing. Regularly review supplier performance and material quality to ensure that your initial assessments hold true over time. This proactive management will safeguard your business against disruptions and maintain product quality.

Researching Potential Suppliers in the Chemical Industry

When researching potential suppliers in the chemical industry, it is crucial to begin with a comprehensive understanding of your specific requirements. This includes not only the types of chemical raw materials needed but also their desired quality standards, regulatory compliance, and delivery timelines. Establishing clear specifications will enable you to communicate effectively with potential suppliers and set realistic expectations.

Once you have defined your requirements, the next step is to identify and evaluate potential suppliers. Utilize industry trade shows, online marketplaces, and professional networks to compile a list of companies. Pay attention to their reputation in the market, which can often be gauged through reviews, testimonials, and their history of compliance with safety and environmental regulations. Additionally, consider conducting preliminary assessments through site visits or audits to gain insights into their manufacturing processes and quality control measures. By thoroughly vetting suppliers, you can ensure that you are sourcing materials from reliable sources that align with your business values and objectives.

Evaluating Supplier Credentials and Quality Assurance Practices

When sourcing chemical raw materials for business needs, evaluating

supplier credentials and

quality assurance practices is paramount.

According to a report from the

World Chemical Export Federation, approximately

30% of supply chain disruptions

in the chemical industry can be traced back to insufficient supplier evaluations.

This underscores the necessity for businesses to meticulously assess potential suppliers

before finalizing contracts. Key factors to consider include the supplier's

certifications, such as ISO 9001, which ensures

that they adhere to international quality management standards. Suppliers with these

certifications often have robust quality assurance protocols which can mitigate risks

associated with material quality and regulatory compliance.

Additionally, understanding a supplier's track record is essential in evaluating their

reliability. The American Chemical Society highlights that companies in the

chemical sector benefit significantly from conducting audits and site visits to verify

a supplier's operational standards. Engaging in this level of due diligence

can lead to identifying suppliers that not only provide high-quality raw materials but

also demonstrate consistent performance and reliability. Furthermore, leveraging technology

for supplier assessment, such as digital platforms that compile supplier performance data,

can enhance transparency and facilitate informed decision-making in sourcing quality materials.

Negotiating Pricing and Terms for Chemical Raw Materials

Negotiating pricing and terms for chemical raw materials is a crucial aspect of supply chain management that can significantly impact a company’s bottom line. According to a report by the Supply Chain Management Review, raw material costs account for over 60% of production expenses in the chemical industry. This makes effective negotiation strategies essential for maintaining profitability. To achieve favorable terms, businesses should prepare detailed analyses of market trends, historical pricing data, and the specific requirements of their operations. For instance, industry data from the Chemical Market Insights report highlights that average pricing for key chemicals can fluctuate significantly based on global supply and demand dynamics, making timely negotiations imperative to lock in competitive rates.

Moreover, establishing strong relationships with suppliers can lead to better negotiation outcomes. As noted in a study from the Institute of Supply Management, companies that foster collaborative partnerships often benefit from flexible payment terms and priority access to quality materials. When negotiating, businesses should clearly communicate their needs while being open to understanding the supplier's constraints. This approach not only leads to improved pricing but can also enhance supply reliability.

Leveraging data analytics tools to anticipate market shifts and aid negotiations can further result in cost savings. The industry’s reliance on key performance indicators, as discussed in the Global Chemical Industry Trends report, emphasizes the importance of negotiating both price and service terms to create a win-win scenario for all parties involved.

Establishing Long-term Relationships with Reliable Suppliers

Establishing long-term relationships with reliable suppliers of chemical raw materials is essential for businesses aiming to maintain a consistent and high-quality production process. According to a recent report by the Chemical Industry Association, companies that engage in collaborative partnerships with trusted suppliers see a 25% improvement in their supply chain efficiency. This improvement arises from better communication and alignment of goals, which in turn leads to enhanced product quality and reduced lead times. Suppliers who understand your specific needs can provide tailored solutions and innovations that drive your business forward.

Building these relationships requires a strategic approach. Start by conducting thorough due diligence on potential suppliers, including assessing their quality certifications and financial stability. A study by McKinsey found that 70% of businesses consider supplier reliability as a critical factor in their sourcing strategy. Once you identify potential partners, invest time in fostering direct communication and transparency. Regular meetings, performance reviews, and joint problem-solving can strengthen these ties, ensuring that you have a dependable source of materials, even in fluctuating market conditions. Moreover, nurturing these relationships can result in negotiated pricing benefits and early access to new products, both vital for maintaining competitiveness in today’s dynamic chemical market.

Quality Chemical Raw Materials Sourced by Supplier Type

Related Posts

-

How to Choose the Right Chemical Company for Your Business Needs

-

Top 10 Essential Chemicals in Chemistry You Need to Know

-

2025 How to Optimize Reagent Manufacturing for Maximum Efficiency

-

2025 How to Source High-Quality Plastic Raw Materials Efficiently

-

Top 10 Bulk Chemicals You Need to Know for Your Industry

-

Top 10 Reagent Chemicals You Need for Your Laboratory Experiments

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch