Top 10 Bulk Chemicals You Need to Know for Your Industry

In the vast and intricate world of industrial manufacturing, bulk chemicals play a pivotal role in various sectors, from agriculture to pharmaceuticals. As defined by industry expert Dr. Emily Carter, a leading chemist with over two decades of experience in chemical production, "Understanding the dynamics of bulk chemicals is essential for optimizing production processes and ensuring sustainable practices in any manufacturing operation." This statement underscores the significance of familiarizing oneself with the top bulk chemicals that are indispensable across diverse industries.

Navigating the landscape of bulk chemicals is not only crucial for enhancing operational efficiency but also for fostering innovation and meeting regulatory standards. With an ever-increasing demand for performance and sustainability, industries must be well-versed in the key chemicals that can drive their success. From feedstocks for petrochemical production to catalysts that enhance chemical reactions, a comprehensive knowledge of these substances can lead to more strategic decision-making and improved environmental compliance.

As we delve into the top 10 bulk chemicals you need to know for your industry, we will explore their applications, economic impact, and the technological advancements shaping their future. This knowledge is vital not just for industry professionals but also for stakeholders looking to navigate the complexities of modern manufacturing.

Understanding Bulk Chemicals: Importance in Various Industries

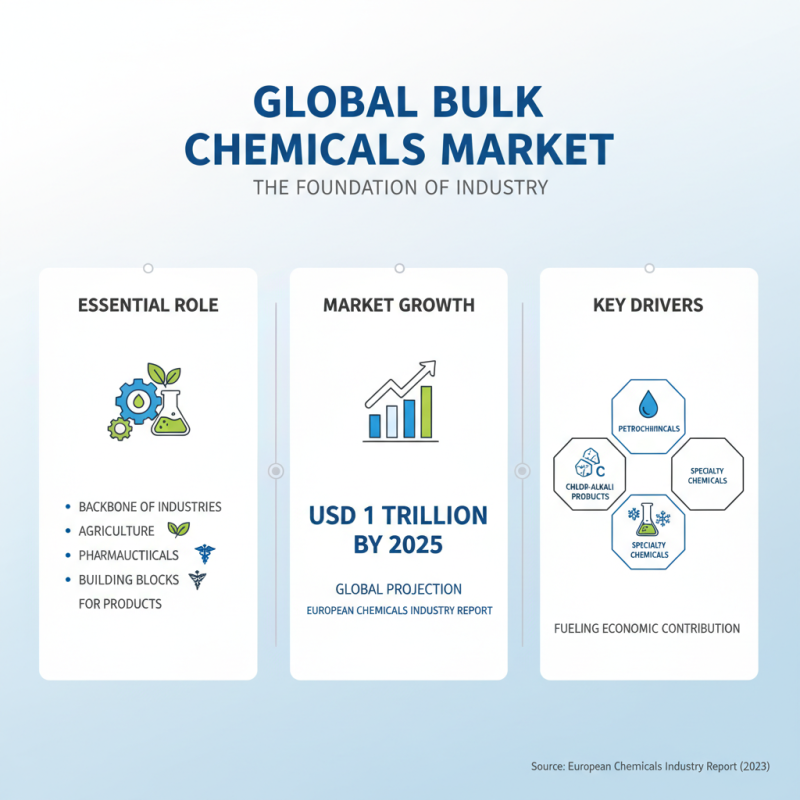

Bulk chemicals play an integral role in the backbone of various industries, from agriculture to pharmaceuticals. Their importance cannot be understated, as they serve as the building blocks for countless products. According to a recent report by the European Chemicals Industry, the global bulk chemicals market is projected to reach USD 1 trillion by 2025, indicating a substantial growth trajectory. The demand for these chemicals is fueled by various sectors, including petrochemicals, chlor-alkali products, and specialty chemicals, which contribute to the economy by providing essential materials for further production processes.

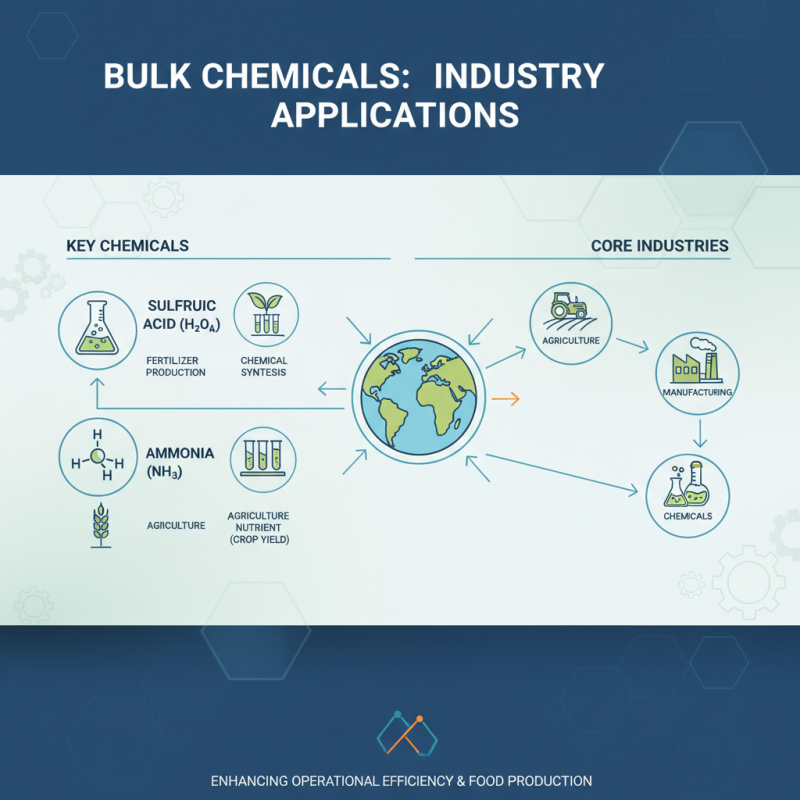

When considering the significance of bulk chemicals, it is crucial to recognize their multifaceted applications. For instance, ammonia is predominantly used in fertilizers, which are critical for ensuring food security. Additionally, sulfuric acid, one of the most produced industrial chemicals, is vital for mineral processing and battery production. This interdependence illustrates how bulk chemicals not only support their respective industries but also contribute to the overall economic infrastructure.

Tips: To effectively manage bulk chemical procurement, companies should regularly assess inventory levels to avoid overstocking or shortages. Establishing strong relationships with reliable suppliers can also enhance supply chain efficiency, ensuring timely availability of essential materials for production processes. Additionally, keeping abreast of market trends and forecasts can aid in strategic planning and cost management.

Top 10 Essential Bulk Chemicals and Their Applications

When it comes to bulk chemicals, understanding their applications can greatly enhance operational efficiencies across various industries. These essential chemicals play pivotal roles in sectors ranging from agriculture to manufacturing. For instance, sulfuric acid is not only a key player in fertilizer production but also serves as a crucial reagent in various chemical syntheses. Similarly, ammonia is utilized extensively in fertilizers, serving as a vital nutrient source for crops, enhancing yield and food production.

Tips: Always consider the environmental impact of using bulk chemicals. Proper management and adherence to safety regulations are essential to mitigate risks associated with chemical handling. Training staff to understand the uses and potential hazards of these chemicals can lead to more efficient and safer workplace practices.

In addition to sulfuric acid and ammonia, sodium hydroxide, widely known for its utility in soap production and as a pH regulator, holds importance in numerous industrial applications. Its effectiveness in chemical manufacturing processes makes it indispensable. Ethylene glycol, another significant bulk chemical, is primarily used in antifreeze formulations and as a precursor for various polymers. Understanding these applications not only aids in regulatory compliance but also fosters innovation in product development and process optimization.

Tips: Keep abreast of the latest advancements in chemical technology and applications. This knowledge can aid in streamlining operations while ensuring compliance with regulations, thus enhancing competitiveness in the market.

Key Properties and Classifications of Bulk Chemicals

Bulk chemicals are essential in various industries, serving as the foundation for numerous products and processes. These chemicals can be broadly classified into several categories based on their key properties, which include their molecular structure, physical state, and reactivity. Understanding these classifications is crucial for selecting the appropriate chemicals for specific applications, such as manufacturing, agriculture, and construction.

One of the primary classifications of bulk chemicals is based on their physical state: solids, liquids, and gases. Solid bulk chemicals, like bicarbonates and phosphates, often serve as additives or raw materials in various formulations. Liquid bulk chemicals, such as acids and alcohols, are frequently used in chemical reactions and industrial processes. Gaseous bulk chemicals, including ammonia and carbon dioxide, play pivotal roles in production and environmental applications. Moreover, reactivity and stability are also important characteristics, differentiating between reactive chemicals that require careful handling and stable ones that can be stored and transported with minimal precautions.

Overall, an in-depth understanding of the properties and classifications of bulk chemicals is crucial not only for regulatory compliance but also for optimizing industrial processes and ensuring the safety of operations. This knowledge empowers industries to make informed decisions regarding chemical selection and usage, thus enhancing operational efficiency and productivity.

Market Trends and Future Outlook for Bulk Chemical Production

The bulk chemicals industry is experiencing significant growth driven by various market trends and evolving consumer demands. According to a recent market analysis, the global bulk chemicals market is projected to reach USD 1.2 trillion by 2025, growing at a compound annual growth rate (CAGR) of 4.5%. This expansion is largely influenced by increasing industrial applications, particularly in sectors such as agriculture, pharmaceuticals, and construction. The demand for eco-friendly chemicals is also on the rise, prompting manufacturers to innovate and adapt their production processes to be more sustainable, which includes transitioning toward bio-based and renewable sources of raw materials.

As we look toward the future, the bulk chemicals sector must navigate several challenges and opportunities. One major trend is the integration of digital technologies within production processes, which enhances efficiency and reduces costs. Industry reports indicate that nearly 60% of companies are investing heavily in automation and smart technologies to streamline operations. Additionally, regulatory pressures regarding environmental impact will increasingly shape the market landscape, with businesses prioritizing compliance and sustainability. The shift towards circular economy principles is fostering collaboration among stakeholders, encouraging practices that minimize waste while maximizing resource utilization. Overall, the future of bulk chemical production is set for a transformative journey, aligning with global sustainability goals and technological advancements.

Top 10 Bulk Chemicals Market Trends

Safety and Regulatory Considerations in Bulk Chemical Handling

Handling bulk chemicals in any industry requires strict adherence to safety and regulatory guidelines to protect workers, the environment, and the integrity of the operation. One of the primary considerations is the establishment of a comprehensive safety management system. This system should include training for personnel on the proper handling and storage of chemicals, as well as the use of personal protective equipment (PPE). Regular drills and updates on safety protocols can ensure that employees are well-prepared to manage spills, leaks, or other emergencies that may arise.

Regulatory compliance is another crucial aspect of bulk chemical handling. Industries must adhere to local, national, and sometimes international regulations that govern the use, transportation, and disposal of chemicals. This includes proper labeling of containers, maintaining Material Safety Data Sheets (MSDS), and conducting regular risk assessments to identify potential hazards. Failure to comply with these regulations can result in significant fines, legal action, and jeopardized public safety. Therefore, it is imperative for organizations to stay informed about regulatory changes and implement necessary practices to ensure compliance and secure the wellbeing of everyone involved.

Related Posts

-

How to Choose the Right Chemical Company for Your Business Needs

-

Top 10 Reagent Chemicals You Need for Your Laboratory Experiments

-

2025 How to Optimize Reagent Manufacturing for Maximum Efficiency

-

Unlocking the Future: Top 2025 Essential Cosmetic Raw Materials Trends

-

Top 10 Essential Chemicals in Chemistry You Need to Know

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch