Top Trends in Chemical Industries in the UK for 2025 and Beyond

As the landscape of the chemical industries in the UK continues to evolve, industry experts are predicting significant trends that will shape the future of this vital sector by 2025 and beyond. Dr. Emma Thompson, a renowned analyst in the field, highlights the critical importance of innovation in driving sustainable practices and economic growth within the sector. "The chemical industries in the UK must embrace cutting-edge technologies to enhance efficiency and environmental stewardship as we move forward," she emphasizes.

In recent years, the UK has seen a growing emphasis on sustainability and digital transformation within its chemical sectors. These trends are not only reshaping production processes but also redefining supply chains, with a strong focus on reducing carbon footprints and enhancing resource efficiency. As we approach 2025, the integration of artificial intelligence and blockchain technologies promises to revolutionize operations, enabling companies to respond rapidly to market demands while ensuring compliance with stringent regulations.

The future of the chemical industries in the UK is undoubtedly intertwined with advancements in research and development, fostering collaborations between businesses and academic institutions. This synergy will be crucial in addressing global challenges such as climate change, providing the groundwork for a more sustainable and resilient industry landscape. As we delve into the top trends shaping this sector, it is essential to reimagine the role of innovation as a catalyst for change, paving the way for a thriving future in the chemical industries in the UK.

Emerging Sustainable Practices in the UK Chemical Industry

The UK chemical industry is on the brink of a transformative shift towards sustainable practices, driven by regulatory pressures and societal demands for environmental responsibility. A recent report by the Chemical Industries Association predicts that by 2025, over 50% of chemical production processes will incorporate green chemistry principles, emphasizing efficiency and minimal waste. This transition is not just an ecological necessity; reports indicate that companies embracing sustainable methods can achieve cost savings of up to 20% in operational expenses.

To effectively implement sustainable practices, companies are beginning to adopt lifecycle assessment (LCA) when evaluating their products. By analyzing the environmental impact at each stage of a product’s life, organizations can identify opportunities for improvement. For instance, a notable trend is the development of circular economy strategies that emphasize recycling and reusing materials, drastically reducing the industry's reliance on virgin resources and minimizing landfill waste.

**Tip:** Companies should explore partnerships with research institutions to stay at the forefront of innovations in sustainable technologies. Collaborating on projects can lead to accelerated adoption of green practices and access to cutting-edge advancements in chemical production. Additionally, regular training of employees on sustainability principles can foster a culture of environmental stewardship within the organization, enhancing overall productivity and corporate responsibility.

Top Trends in Chemical Industries in the UK for 2025 and Beyond - Emerging Sustainable Practices in the UK Chemical Industry

| Trend | Description | Projected Impact | Timeline |

|---|---|---|---|

| Circular Economy | Increased focus on recycling and reusing materials in chemical processes. | Reduction of waste by 25% by 2025. | 2025 and beyond |

| Green Chemistry | Adopting methodologies that minimize the use of hazardous substances. | Improved safety and reduced environmental footprint. | 2023-2025 |

| Carbon Neutrality | Efforts to achieve net-zero carbon emissions across operations. | Decrease in greenhouse gas emissions by 50% by 2030. | 2025-2030 |

| Sustainable Supply Chains | Building more resilient and environmentally conscious supply chains. | Enhanced sustainability ratings and reduced operational risks. | 2024-2026 |

| Digital Transformation | Utilizing AI and IoT for efficient resource management and process optimization. | Increased production efficiency by 20% by 2025. | 2023-2025 |

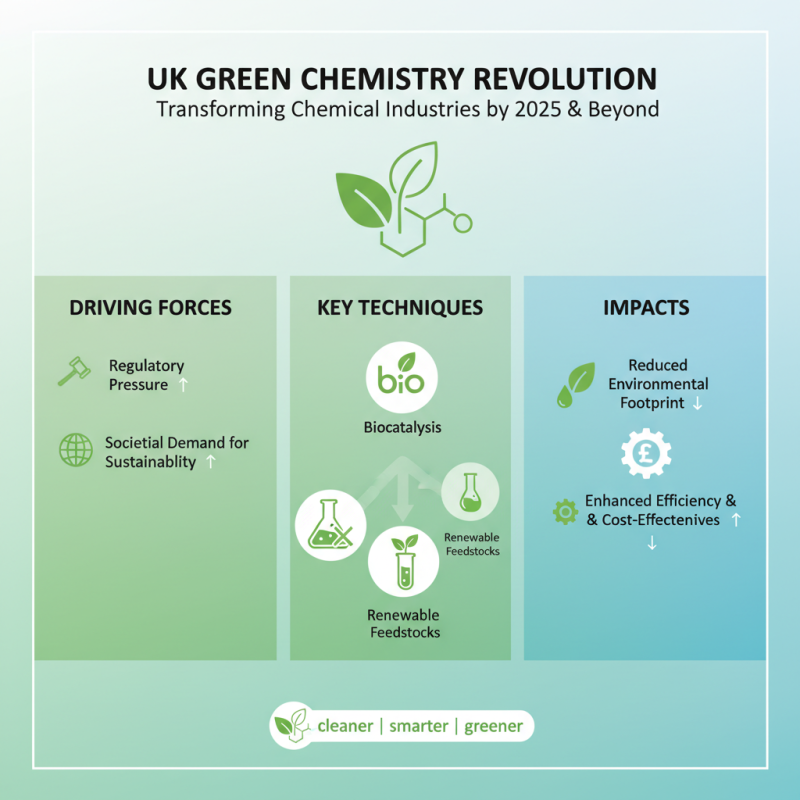

Advancements in Green Chemistry Techniques for 2025

The advancement of green chemistry techniques is poised to transform the chemical industries in the UK by 2025 and beyond. With increasing regulatory pressures and a growing societal demand for sustainability, companies are leveraging eco-friendly methods to minimize waste and energy consumption. Techniques such as biocatalysis, solvent-free reactions, and the use of renewable feedstocks are becoming more prevalent. These innovations not only reduce the environmental impact but also enhance the efficiency of chemical processes, leading to more cost-effective production methods.

Moreover, the incorporation of artificial intelligence and machine learning in the development of green chemistry is paving the way for smarter, more sustainable solutions. Predictive analytics can help identify optimal reaction conditions and reduce trial-and-error periods in research and development. Additionally, the integration of life cycle assessments (LCA) in the design phase ensures that environmental considerations are prioritized from the outset, enabling a circular economy approach within the chemical sector. As the industry embraces these advancements, UK chemical companies are likely to position themselves as global leaders in sustainable practices by fostering innovation in green chemistry.

The Impact of Digital Transformation on Chemical Manufacturing

Digital transformation is set to revolutionize the chemical manufacturing sector in the UK, enhancing efficiency and productivity while reducing operational costs. As per a recent report by the Chemical Industries Association, the UK chemical industry is projected to reach a market value of £20 billion by 2025, largely driven by technological advancements. Automation and data analytics are at the forefront of this transformation, enabling real-time monitoring of production processes, which can lead to significant decreases in waste and energy consumption. According to a study from McKinsey, companies that implement these digital solutions can boost their productivity by up to 30%, highlighting the potential benefits of embracing technology in the chemical manufacturing landscape.

Furthermore, the integration of the Internet of Things (IoT) and artificial intelligence (AI) is facilitating smarter supply chain management and enhanced overall safety measures within chemical plants. A report by Deloitte indicates that AI applications can improve operational safety by predicting potential hazards and enabling preventative measures. This proactive approach not only protects workers but also ensures regulatory compliance, which is increasingly necessary in the evolving regulatory landscape. As the UK chemical industry navigates towards a more sustainable and technologically advanced future, digital transformation will undoubtedly play a critical role in shaping its path forward.

Top Trends in Chemical Industries in the UK for 2025 and Beyond

This chart illustrates the projected impact of digital transformation on various sectors of the chemical manufacturing industry in the UK by 2025. The data highlights anticipated growth across different areas driven by innovative technologies.

Regulatory Changes Affecting the UK Chemical Sector in the Coming Years

The UK chemical sector is poised for significant transformation due to a series of regulatory changes anticipated in the coming years. As the government seeks to enhance environmental protection and sustainability, new regulations will likely focus on reducing carbon emissions and promoting greener manufacturing processes. This shift is in alignment with the UK's broader commitments to combat climate change, which means that chemical manufacturers will need to adapt their practices to comply with stricter environmental standards.

Moreover, the regulatory framework surrounding chemical safety is becoming increasingly robust. Changes to the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regime are expected to tighten the controls on chemical substances, ensuring their safe use and minimizing risks to human health and the environment. This could involve more detailed reporting requirements and increased scrutiny of chemical practices, compelling companies to invest in research and development for safer alternatives. The industry must stay ahead of these changes to ensure compliance, which could ultimately drive innovation within the sector as companies look to develop new technologies that align with these emerging regulations.

Key Innovations in Chemical Recycling and Waste Management Strategies

In the UK, the chemical industry is undergoing a transformative phase, particularly in the realm of chemical recycling and waste management. According to a recent report by the UK Chemical Industries Association, it is projected that the chemical recycling market will grow substantially, with an expected value of £1.5 billion by 2025. This growth is driven by advancements in technology that allow for more efficient processing of waste materials into reusable resources, thereby enabling a circular economy within the sector. Innovations such as advanced pyrolysis and chemical depolymerization are becoming crucial, turning plastic waste back into usable feedstock for chemical production.

Investing in sustainable waste management strategies is also becoming increasingly important. The Environmental Agency estimates that improving waste management systems could reduce landfill costs by up to 25% for companies, while fostering a responsible approach towards waste disposal that aligns with governmental regulations and public expectations. The implementation of technologies like artificial intelligence for waste sorting and blockchain for tracking waste materials is essential in enhancing transparency and efficiency in waste management processes.

Tips: To stay ahead in the evolving landscape of chemical recycling, companies should consider integrating digital solutions that streamline operations and provide real-time data analytics. Furthermore, fostering partnerships with research institutions can drive innovation and efficiency, ensuring continuous improvement and adaptation to industry trends. Emphasizing employee training on new technologies will also be pivotal in maximizing the benefits of these advanced waste management strategies.

Related Posts

-

Top 10 Essential Chemicals in Chemistry You Need to Know

-

Top 10 Bulk Chemicals You Need to Know for Your Industry

-

How to Choose the Right Chemical Company for Your Business Needs

-

2025 How to Optimize Reagent Manufacturing for Maximum Efficiency

-

2025 How to Source High-Quality Plastic Raw Materials Efficiently

-

Unlocking the Future: Top 2025 Essential Cosmetic Raw Materials Trends

Contact Us

We offer a just-in-time delivery solution supplying the highest quality materials to our customers. Get in touch today and learn how we can help your company.

Get in touch